CNC Turning Machines

HYB-32 : CNC Turning Machines

• Compact Footprint

• Servo and Cam drive combination

• Overlapping Operations

• High Productivity

• Ergonomic and User friendly

• Aesthetically Sound

• Economic

• Patented Design

Abhijat make innovative HYB-32 is designed to provide customer value for money by virtue of smart kinematic combination of full version CNC lathe and proven Traub principles. The machine provides convenient operating facility, rigidity, high accuracy and short machining times due to overlapped operations.

The product provides both Repeatability and Accuracy The machine has a strong, rigid buildup and facilitates simultaneous machining by using Servo motor driven CNC slides and cam driven mechanical vertical slides. The high power motor enables high accuracy machining with good surface finish for turned parts of up to 32 mm diameter. LM guides and ball screws are used in both slides ensuring smooth and consistent axial movements.

The machine is designed to be compact thus saving on space. The auto controlled vertical slides provide wide range of cycles to be set for the machine. Aesthetically and Ergonomically designed guarding is provided to ease operation visualization and the user-friendly HMI are provided with the machine.

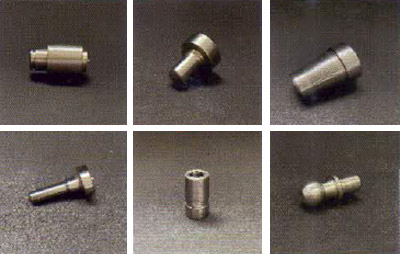

Components proved on machine

Compact Auto-CNC Machine HYB-32

Basic Machine Consists of :

CNC System Details:

Optional Machine Features: